摄像头全自动生产线

优点介绍

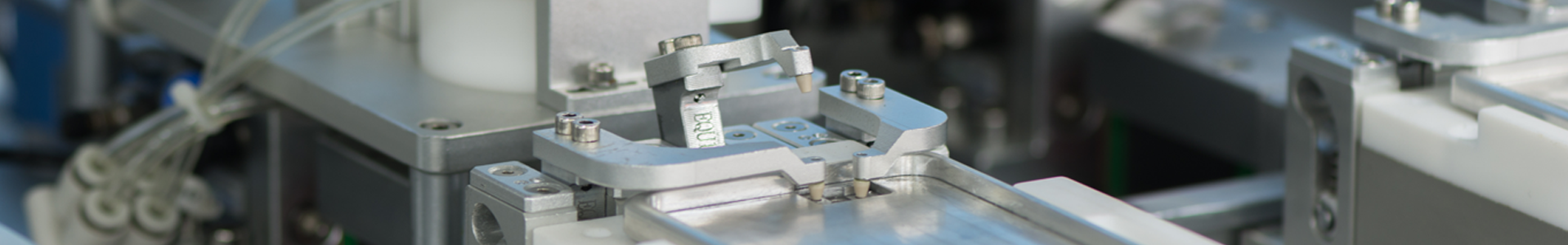

自动化线体应用于千级无尘车间,设备采用高精密模组和机械手,对产品进行多面绕组,结合相机实时对位,实现高精度组装。同时采用PID&PLC load cell系统和加热系统,精准控制产品加热固化过程中压力和温度。设备自带附件功能,实时补偿。

The automation line is applied in a class 1000 cleanroom workshop. The equipment is using high-precision modules and robot to perform multi sided winding on the product with real-time camera alignment to achieve high-precision assembly. PID&PLC load cell system and heating system are working for precise control of force and temperature during product heating and curing process. The equipment also enables real-time compensation.

参数配置

采用500万CCD 引导组装采用精密模组,精度0.02mm

PID&PLC load cell系统和加热系统

千级无尘车间

CCD*2套/台组装机

整线物料使用达到1000级无尘要求

双组装工位

2套四轴无尘机械手/台组装机

38轴/台组装机

设备精度:±0.02mm

UPH:900

Assembly guided by 5-megapixel CCD

Using precision modules with an accuracy of 0.02mm

PID&PLC load cell system and heating system

Class 1000 cleanroom standard

CCD * 2 sets/assembly machine

The use of materials of the whole line meets Class 1000 Cleanroom requirement

Dual assembly station

2 sets of four axis dust-free robotic arms/assembly machine

38 axes/assembly machine

Equipment accuracy: ± 0.02mm

UPH: 900

功能描述

把排线组装在指定摄像头模组上,加热固化Assemble flex onto the designated camera module trough heating and curing