电子手表配件模块全自动生产线

优点介绍

OP上料载具,通过流水线,将载具传递至元器件组装站,并且顶升定位载具;

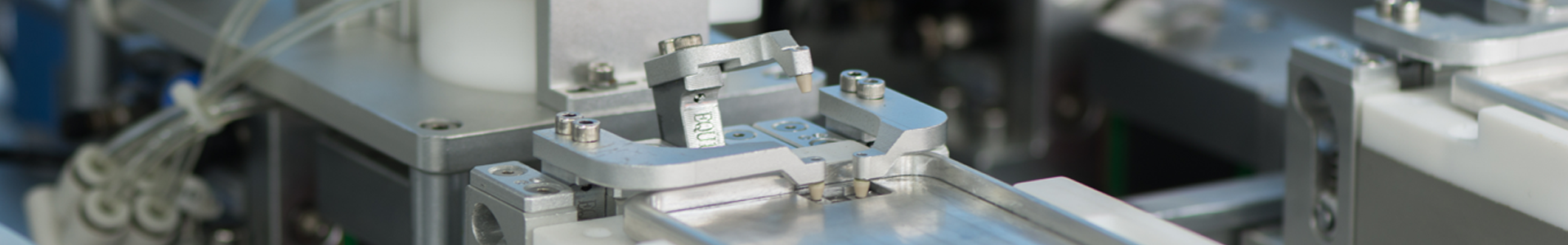

OP上料产品料盘(间隔1h),通过CCD定位、扫码枪扫码识别SN,精准取料,并且计算矫正产品,机械手通过位置补偿将排线、Foam、元器件进行准确贴装并锁螺丝;CCD对产品进行复检量测反馈每个产品组装精度。

软件通过SN扫码,便于绑定每个产品SN,对产品后期维护、溯源起到关键作用,满足工厂对于智能生产的需求。

OP loads carrier。 Carrier is flowed to assembly station, where carriers are lifted for positioning.

OP loads materials every 1 hour. It involves auto CCD locating, SN scanning , accurately picking up materials. Robot pick up and place flex, foam and related components with CCD guidance and then lock screws.CCD conducts re inspection, measurement and feedback on the assembly accuracy of each product.

The software scans the SN code making it easy to link each product SN, which is crucial in maintenance and traceability so as to meet the factory's needs for intelligent production.

参数配置

采用500万像素CCD进行配件定位;采用精密模组、四轴机械手,实现高速、高精度生产能力自动化程度高、实现自动上下料、自动检测等多项功能

设备通用性强,可以实现多种规格产品生产

整线布局设计合理,迭代升级简单,方便

设备空间设计合理,方便维护

机械手7台/整线

设备精度:±0.1mm

UPH:300

Using 5-megapixel CCD for components positioning; Adopting precision modules and four-axis robot to achieve high-speed and high-precision production capacity

High percentage of automation-achieving multiple functions such as auto loading and unloading, auto inspection, etc

The equipment is universal designed, which is compatible for different configs production.

Reasonable layout design enables low cost and convince for upgrading

Reasonable design of equipment space for easy maintenance

7 robots/whole line

Equipment accuracy: ± 0.1mm

UPH: 300

功能描述

将电子手表内部模块元件进行自动化上料、贴Foam、撕膜、折弯、量测、组装,、锁螺丝等一系列流程Involve the process of auto loading, film attachment, linear removal, pre-bend, measurement,assembly and screw locking