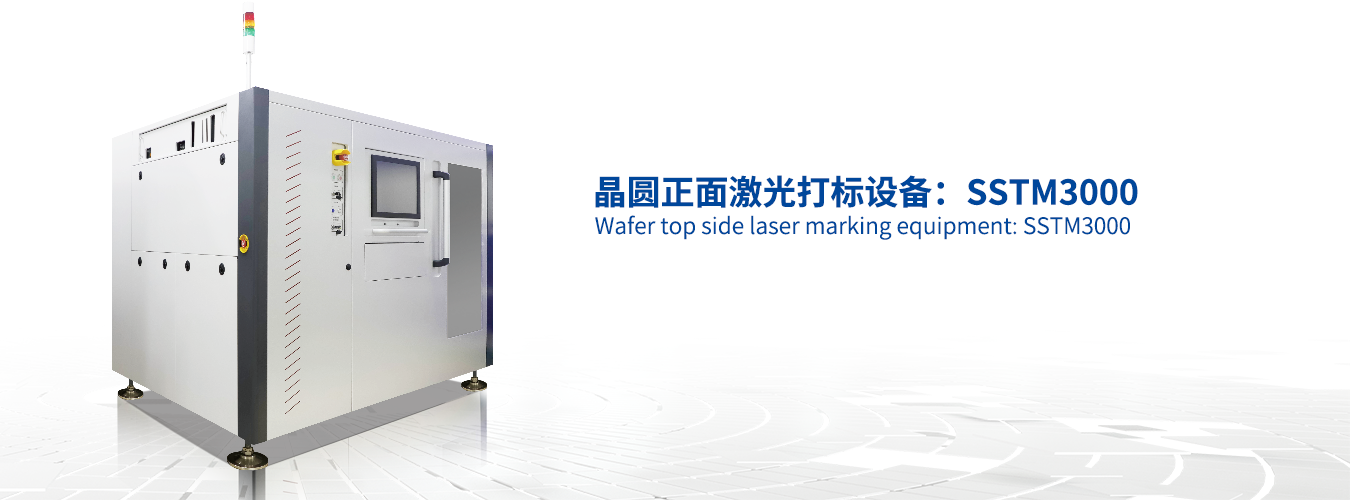

晶圆正面激光打标设备:SSTM3000

优点介绍

具有激光功率自动补偿功能

可用于晶圆ID打标/特殊芯片打标/不合格芯片打标

配有金属料盒/拾取&放置/定位相机/OCR识别/打标头,用于激光打标和实时监控打标位置和晶圆打标识别

配有 振镜自动校正功能,自动偏移补偿功能和铁环晶圆中心补正功能

可自动切换打标模式为 晶圆ID打标/不合格芯片打标/特殊芯片打标

Equipped with laser power automatic compensation function

Can be used for wafer ID marking / reference die marking / rejected die marking.

Equipped with metal cassettes / pick & place / align vision / OCR reader / marking head , for laser marking and real-time monitoring of marking positions and wafer marking recognition.

Equipped with automatic scanner calibration , automatic offset compensation, and iron ring wafer center compensation functions

Automatic switching of marking mode for wafer ID / rejected die / reference die marking

参数配置

功能描述

适用产品:铁环 8英寸、12英寸晶圆主要功能:在晶圆正面实现晶圆ID打标/不合格芯片打标/特殊芯片打标

进出料方式:金属料盒、铁环晶圆

设备尺寸:L2200 * W2000 * H1850mm

Applicable products: 8-inch, 12 inch wafers mounted on ring frame carrier.

Main function: To achieve laser marking for wafer ID/rejected die/

reference die on the wafer front side

Import and export method: Metal Cassettes,Ring Frame wafer

Size: L2200 * W2000 * H1850mm