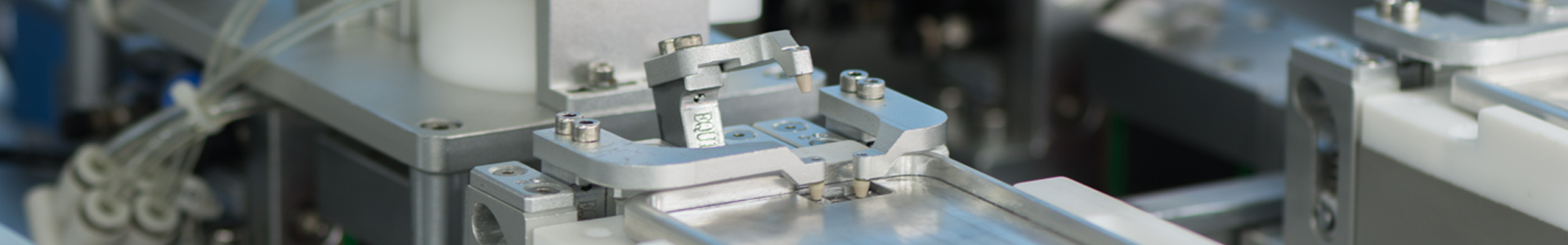

摄像头全自动生产线

优点介绍

整条自动化线体应用于千级无尘车间,设备采用高精密线马模组和音圈电机,对产品进行整版组装,结合高速飞拍相机,实现快速高精度组装。组装加热工站,采用分段顶升设计实现产品组装和加热固化于一体,从而保证了产品精度。整线配备复检工站,对产品进行2D/3D多项数据检测,同时可以实时补偿。

The whole automation production line is applied to a class 1000 cleanroom workshop. The equipment is using high-precision linear motor and voice coil motor to assemble the product, working with with high-speed flying cameras to achieve fast and high-precision assembly. The assembly heating station adopts a segmented lifting design to integrate product assembly and heating curing to ensure product accuracy. The entire line is equipped with an inspection station, which performs 2D/3D multiple data detection and real-time compensation.

参数配置

高精密线马模组配音圈电机,实现高速高精度组装一体式组装加热工站设计

千级无尘选型

2D/3D多项数据检测

采用500万像素CCD

CCD*2套/台组装机

整线物料使用达到1000级无尘要求

龙门模组1套/台组装机

音圈电机4套/台组装机

12轴/台组装机

设备精度:±0.01mm

UPH:1200

High precision linear motor works with group voice coil motor to achieve high-speed and high-precision assembly

Design of integrated heating station to assembly station

Class 1000 cleanroom standard

2D/3D multiple inspection data

Using a 5-megapixel CCD

CCD * 2 sets/assembly machine

The use of materials of the whole line meets Class 1000 Cleanroom requirement

1 set of gantry module/assembly machine

4 sets of voice coil motors / assembly machine

12 axes/assembly machine

Equipment accuracy: ± 0.01mm

UPH: 1200

功能描述

把线圈组装在指定排线上,加热固化Assemble coil onto the designated flex, heat and cure it